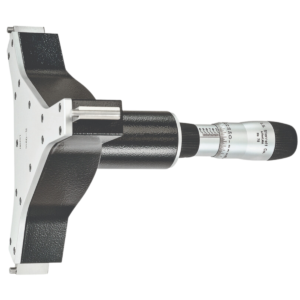

Product Description

The 78XTZ-750 Bore Gage features extended travel, reducing the need to exchange anvils. The ground contact points seat the internal micrometer faster and more accurately than the spherical contacts found in other gages. The rugged and accurate 78XTZ series internal micrometers are available individually or in economical sets from .080-12″ (2-300mm).

Designed to measure internal cylindrical holes and grooves, this gage can measure in metal, plastics, and other materials. The 78XTZ-750 features a 3-point contact with a hardened point to ensure accurate measurements. The 2-7/16″ measuring depth allows this model to measure holds up to 3 inches deep.

Features

- Wide measurement range without changing anvils

- Tungsten carbide measuring faces on all 3-point heads above 1/2″ (12.5mm)

- Ratchet stop ensures consistent measurements

- Self-centering contacts for true readings

- Blind bore measuring capability above 1/2″ (12.5mm) diameter

- Extensions available up to 6″ (150mm) for deep hole measuring

- Setting rings included

- Depth stop/collar also available for .080″-.250″ (1-6mm) range

- Resolution from .0001″ (0.0025mm) on the 2-point contact tools up to 3/4″ (20mm) and .00025″ (0.005mm) on the 3-point contact tools ranging from 3/4″-12″ (20mm – 300mm)

- Each micrometer bore gage comes in a case, complete with setting ring, contacts, wrenches, and instructions

Applications

- Manufacturing

- Machining

- Automotive

- Aerospace

- Energy

- Defense

Uses

- Check bore holes prior to assembly or maintenance

- Check the accuracy of machining operations after completion

- Measure the inside diameter of a hole

- Test the quality of pistons, rods, and sleeves

- Ensure products meet certain size requirements

About Starrett

The L.S. Starrett Company is a world leader in precision measuring tools and instruments. Since 1880, they have been an industry standard. Starrett’s high quality and durability have made the brand an industry standard for decades. They produce products for various industries, including aerospace, automotive, manufacturing, and commercial construction. Today, they’ve expanded into metalworking, making saw blade products for manufacturing operations worldwide.